Your senior estimator catches issues that your junior estimator misses. Not because they're smarter—because they've made more mistakes and built better checklists in their head.

The goal of a bid review SOP is to get that checklist out of their head and into a system everyone follows. Consistent process equals consistent quality.

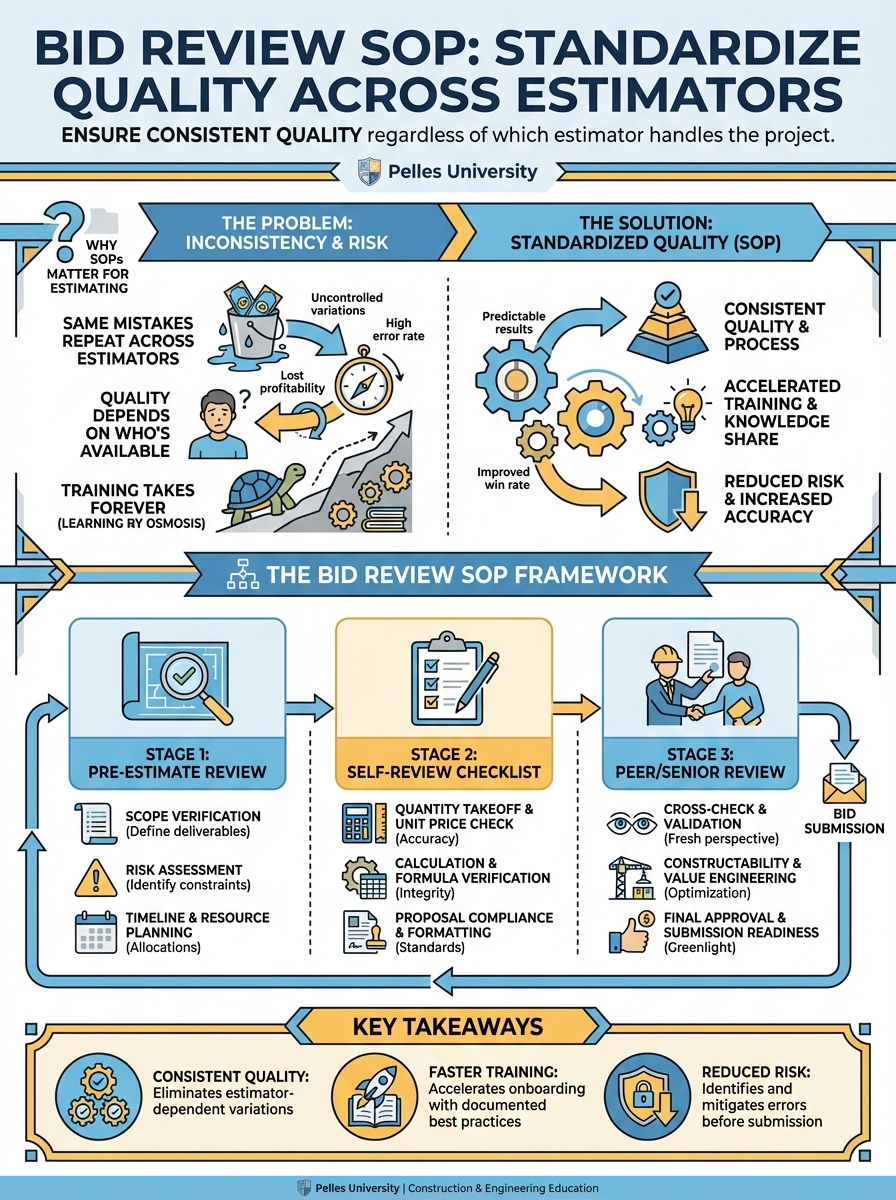

Why SOPs Matter for Estimating

Without a standard process:

- Same mistakes repeat across estimators

- Quality depends on who's available

- Training takes forever (learning by osmosis)

- Senior estimators spend time catching junior mistakes instead of pursuing work

With a standard process:

- Mistakes become trainable moments, not recurring problems

- Any estimator can produce consistent output

- Training has structure

- Senior review focuses on judgment calls, not basic errors

The Bid Review SOP Framework

A complete bid review SOP covers three stages:

- Pre-Estimate Review – Before the estimator starts

- Self-Review – Estimator checks their own work

- Peer/Senior Review – Second set of eyes

Stage 1: Pre-Estimate Review

Before starting the estimate, verify:

Document completeness:

- All drawings received and logged

- All spec sections for your trade obtained

- All addenda received and processed

- Geotechnical/site survey available (if applicable)

Scope understanding:

- ITB requirements extracted to checklist

- Bid form requirements understood

- Addendum acknowledgment requirements clear

- Scope boundaries confirmed (what's in, what's out)

Estimate setup:

- Job set up in estimating software

- Correct labor rates loaded

- Material pricing updated or confirmed

- Takeoff sheets/templates ready

Stage 2: Self-Review Checklist

Before submitting for peer review, the estimator checks:

Takeoff completeness:

- All drawing sheets reviewed

- Equipment schedule quantities match takeoff

- All spec sections reviewed for equipment requirements

- All major systems accounted for

Pricing verification:

- Labor hours reasonable for scope

- Material pricing reflects current market

- Equipment quotes obtained (or allowances noted)

- Subcontractor quotes obtained (or allowances noted)

Math check:

- Extensions verified (quantity × unit = extended)

- Subtotals foot correctly

- Overhead and profit applied correctly

- Alternates calculated correctly

Documentation:

- Inclusions/exclusions list complete

- Clarifications drafted

- Assumptions documented

- Bid form prepared

Stage 3: Peer/Senior Review

The reviewer checks:

Big picture:

- Total price reasonable for project type and size?

- Labor hours per unit align with historical data?

- No major systems missing?

Takeoff spot-checks:

- Verify 2-3 random quantities against drawings

- Check equipment schedule against takeoff

- Verify scope boundaries match inclusions/exclusions

Pricing spot-checks:

- Labor rate appropriate for project conditions

- High-value equipment quotes verified

- Subcontractor quotes competitive

Submission readiness:

- All addenda acknowledged

- Bid form complete and accurate

- Required attachments included

- Delivery method confirmed

The Review Meeting Format

For final review, use a structured meeting:

Duration: 15-30 minutes depending on project size

Attendees: Estimator, reviewer, ops/PM (for large projects)

Agenda:

- Project overview (2 min) – Size, type, GC, timeline

- Scope summary (3 min) – Major systems, key equipment

- Risk/opportunity review (5 min) – What could go wrong, what could go right

- Pricing review (5 min) – Total, breakdown by system, alternates

- Open items (5 min) – Clarifications, outstanding questions

- Go/no-go confirmation (2 min) – Final decision to submit

Output: Written notes on any adjustments, final price confirmation

Building Your Checklists

The checklists above are starting points. Customize based on:

By Trade:

HVAC additions:

- Airflow calculations verified

- Equipment sizing confirmed

- Controls scope defined

Electrical additions:

- Panel schedule complete

- Feeder sizing confirmed

- Low voltage scope defined

Plumbing additions:

- Fixture count verified

- Water heater sizing confirmed

- Medical gas scope defined (if applicable)

By Project Type:

Healthcare additions:

- Infection control requirements reviewed

- Above-ceiling coordination assessed

- Commissioning scope confirmed

Industrial additions:

- Process connections defined

- Equipment access requirements reviewed

- Hazardous area classifications confirmed

Training New Estimators Using the SOP

The SOP becomes your training backbone:

Week 1-2: Observe senior estimator following SOP Week 3-4: Perform takeoff with senior review at each stage Week 5-6: Perform full estimate with checklist, senior review before submission Week 7+: Independent estimating with peer review

Track which checklist items get flagged in reviews. Recurring issues become focused training topics.

Measuring SOP Effectiveness

Track metrics to improve your SOP:

Error rate: Issues caught in review ÷ total bids Error type: Categorize by checklist section (takeoff, pricing, documentation) Time to estimate: Track by project size to establish benchmarks Win rate: By estimator and project type

If certain errors repeat, the SOP needs strengthening in that area.

What's Next

A written SOP is step one. The next step is building it into your workflow—digital checklists that track completion, review templates that standardize feedback, and metrics dashboards that show where the process is working and where it's breaking.

TL;DR

- SOPs turn tribal knowledge into trainable, repeatable process

- Cover three stages: pre-estimate, self-review, and peer/senior review

- Checklists should be customized by trade and project type

- Use structured review meetings with clear agendas and documented output

- Track error rates and types to continuously improve the process