Every completed project is a lesson. The question is whether you're capturing those lessons or letting them walk out the door when the job closes.

The best estimators don't just guess better—they've built systems to learn from every project they've done. Here's how to build yours.

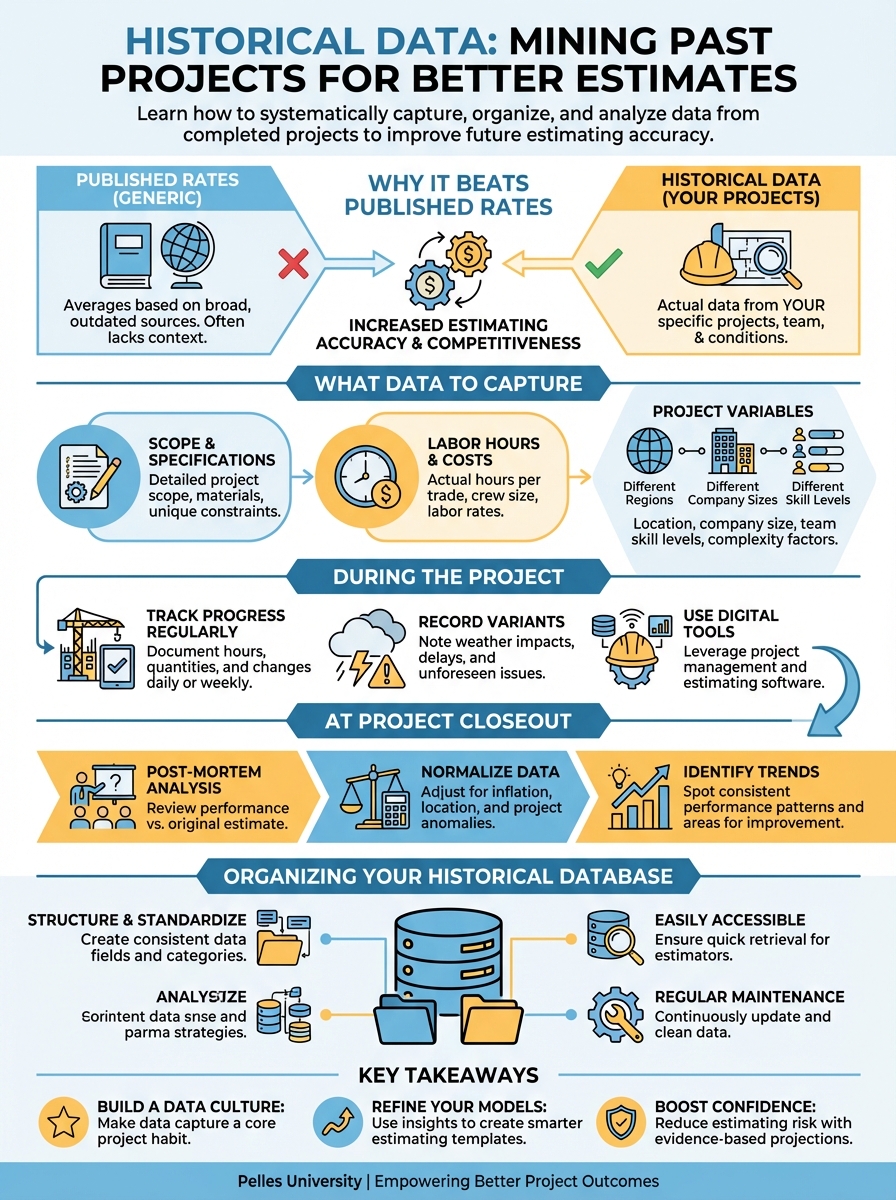

Why Historical Data Beats Published Rates

Industry-published labor rates are averages across:

- Different regions

- Different company sizes

- Different skill levels

- Different methods and tools

Your data reflects your reality:

- Your crews' productivity

- Your methods and equipment

- Your market conditions

- Your management approach

A 20% difference from published rates isn't unusual—and knowing your actual rates is the difference between making money and wondering where it went.

What Data to Capture

During the Project

Labor tracking:

- Hours by task/system

- Crew composition (journeymen vs. apprentices)

- Conditions encountered (access, stacking, weather)

- Delays and their causes

Material tracking:

- Actual quantities vs. estimated

- Waste percentages

- Procurement issues

- Price changes from estimate

Progress tracking:

- Productivity rates achieved

- What slowed things down

- What went better than expected

At Project Closeout

Cost summary:

- Final labor cost vs. estimate

- Final material cost vs. estimate

- Subcontractor cost variances

- Change order net impact

Scope analysis:

- What was actually built vs. estimated

- Scope additions and reductions

- Design changes encountered

Lessons learned:

- What would you estimate differently?

- What conditions weren't anticipated?

- What went well to repeat?

Organizing Your Historical Database

Project Classification

Categorize projects for meaningful comparison:

| Category | Options |

|---|---|

| Building type | Office, healthcare, industrial, retail, education |

| Project type | New construction, renovation, tenant improvement |

| Size range | Small (under $100K), medium ($100K-$500K), large (over $500K) |

| Complexity | Simple, standard, complex |

| GC/client | Track by relationship |

Unit Metrics

Calculate comparable metrics:

By area:

- Cost per square foot

- Labor hours per square foot

- Material cost per square foot

By system:

- Cost per ton (HVAC)

- Cost per fixture (plumbing)

- Cost per device (electrical)

- Cost per head (fire protection)

By unit:

- Hours per linear foot of pipe/conduit

- Hours per diffuser/device

- Hours per fixture

Variance Tracking

For every project, calculate:

- Labor variance (actual vs. estimated)

- Material variance

- Overall variance

- Variance percentage

Track patterns:

- Are you consistently over or under on certain items?

- Which building types have highest variance?

- Which GCs correlate with better/worse outcomes?

Analyzing Your Data

Finding Patterns

Look for correlations:

Query: What factors correlate with labor overruns?

- Building type?

- Project size?

- GC relationship?

- Schedule duration?

- Complexity factors?

Identifying Outliers

When projects significantly beat or miss estimates:

- Document the variance (how much, which categories)

- Identify the cause (scope change? productivity issue? estimating error?)

- Determine if systemic (will this happen again?)

- Adjust accordingly (update rates, factors, or checklists)

Building Benchmarks

From sufficient data, establish:

| Metric | Low | Average | High |

|---|---|---|---|

| Electrical $/SF (office) | $18 | $24 | $32 |

| Plumbing $/fixture | $1,800 | $2,400 | $3,200 |

| HVAC $/ton | $3,500 | $4,500 | $6,000 |

| Fire protection $/head | $180 | $240 | $320 |

Your ranges, based on your history.

Using AI for Historical Analysis

AI can help find patterns in your data:

Pattern Recognition

I have cost data from 50 completed electrical projects including:

- Building type

- Square footage

- Final cost

- Labor hours

- Estimated vs. actual variance

Analyze this data and identify:

1. Average cost per SF by building type

2. Factors that correlate with cost overruns

3. Projects that were outliers and possible reasons

4. Trends over time

Predictive Benchmarking

Based on this historical data, what should I expect for:

- A 50,000 SF office building

- Standard complexity

- 6-month schedule

- New construction

Provide expected ranges for:

- Total electrical cost

- Cost per SF

- Labor hours

- Material cost percentage

Lessons Learned Synthesis

Review these closeout reports from 10 similar projects.

Summarize:

1. Common estimating misses

2. Conditions frequently not anticipated

3. Recommendations that repeat across projects

4. Suggested checklist items for future estimates

Building the Habit

Make Data Capture Easy

- Use templates for project closeout

- Require data as part of closeout process

- Tie to final payment processing

- Keep it simple—capture key metrics, not everything

Review Regularly

- Monthly: Review recent project closeouts

- Quarterly: Update benchmark rates

- Annually: Comprehensive analysis and rate adjustment

Share the Knowledge

- Estimators should see project outcomes

- Project managers should understand estimate assumptions

- Create feedback loops between field and estimating

Quick-Start Historical Data Template

At minimum, capture for every project:

Project info:

- Project name and type

- Square footage

- Contract value

- GC and owner

Cost summary:

- Estimated labor cost → Actual labor cost

- Estimated material cost → Actual material cost

- Net change orders

- Final margin

Key metrics:

- Final cost per SF

- Labor hours per SF

- Major variance explanations

Lessons:

- Top 3 things to estimate differently next time

Common Pitfalls

Pitfall 1: Not Normalizing Data

A project with overtime, difficult access, and trade stacking isn't comparable to one with ideal conditions. Normalize or note conditions.

Pitfall 2: Ignoring Small Projects

Small projects often have higher per-unit costs (mobilization, minimum charges). Track them separately from large projects.

Pitfall 3: Blaming Estimating for Field Issues

Not every variance is an estimating error. Separate:

- Estimating misses (wrong quantities, wrong rates)

- Field issues (productivity problems, rework)

- Scope changes (not estimating's fault)

Pitfall 4: Analysis Paralysis

Start simple. Basic variance tracking beats elaborate systems you don't use.

What's Next

Historical data improves future estimates. But even perfect estimates don't help if you can't collect on your work. Next, look at change order management—documenting and negotiating the extra work that inevitably emerges.

TL;DR

- Your completed project data is more valuable than published industry rates

- Capture data throughout the project and at closeout

- Organize by building type, size, and complexity for meaningful comparison

- Use unit metrics (cost/SF, hours/fixture) to compare different-sized projects

- Analyze patterns and outliers to improve future estimates

- Use AI to find patterns in large datasets

- Start simple—basic tracking beats elaborate unused systems