Your foreman asks a worker to pull wire through conduit overhead. The worker grabs a ladder, climbs up, and starts working.

No JHA. No discussion of hazards. No plan for what happens if the ladder shifts.

This is how incidents happen.

What Is a Job Hazard Analysis?

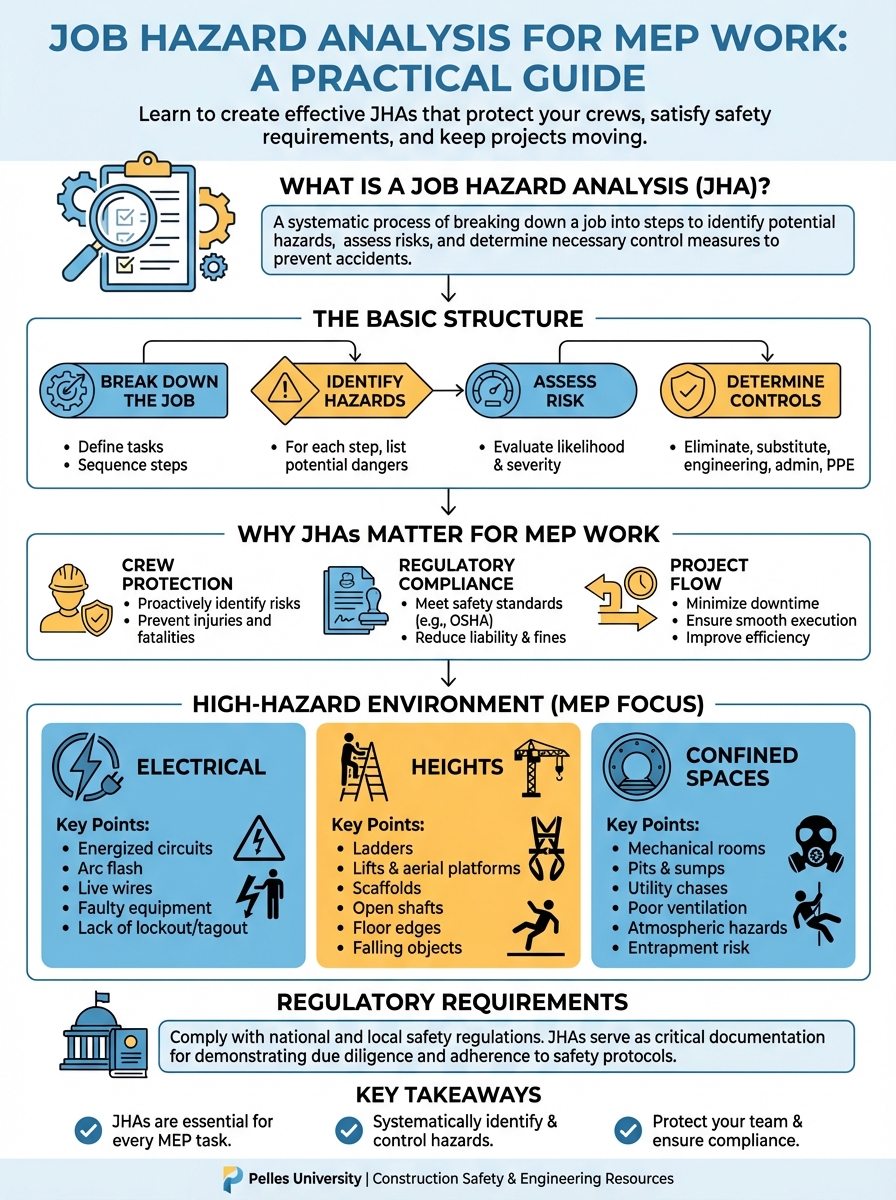

A Job Hazard Analysis (JHA)—sometimes called a Job Safety Analysis (JSA)—is a technique for identifying hazards associated with a task and determining the best way to control them.

It's not paperwork for paperwork's sake. It's a thinking process that prevents injuries.

The Basic Structure

Every JHA answers three questions:

- What are the steps of this task?

- What could go wrong at each step?

- How do we prevent it?

Simple concept. Powerful when done right.

Why JHAs Matter for MEP Work

High-Hazard Environment

MEP work combines multiple hazards:

- Electrical: Energized circuits, arc flash

- Heights: Ladders, lifts, scaffolds, open shafts

- Confined spaces: Mechanical rooms, pits, chases

- Material handling: Heavy equipment, awkward loads

- Environmental: Heat, cold, poor lighting

Each task may involve several of these simultaneously.

Regulatory Requirements

OSHA doesn't specifically require JHAs, but:

- General Duty Clause requires hazard identification

- Many GCs require JHAs for all activities

- Owner safety programs often mandate them

- They demonstrate due diligence

Business Impact

Beyond compliance:

- Fewer injuries = lower EMR = lower insurance

- Fewer incidents = less project disruption

- Better planning = more efficient work

- Documented safety = competitive advantage

Creating Effective JHAs

Step 1: Select the Task

Choose tasks based on:

High priority:

- Tasks with injury history

- New or non-routine work

- High-consequence activities

- Tasks with recent changes

Examples for MEP:

- Installing rooftop equipment

- Working in electrical rooms

- Pulling wire overhead

- Testing fire alarm systems

- Pressure testing piping

Step 2: Break Down the Task

List the basic steps in sequence:

Example: Installing overhead ductwork

| Step | Description |

|---|---|

| 1 | Set up access equipment (lift/scaffold) |

| 2 | Transport duct sections to work area |

| 3 | Install hangers and supports |

| 4 | Lift duct sections into position |

| 5 | Connect sections and seal joints |

| 6 | Secure final connections |

| 7 | Clean up and demobilize |

Keep steps specific enough to identify hazards but not so detailed that the JHA becomes unwieldy.

Step 3: Identify Hazards

For each step, ask:

- What could go wrong?

- What are the consequences?

- Has this caused injury before?

- What environmental factors matter?

Using the ductwork example:

| Step | Hazard |

|---|---|

| Set up lift | Fall from platform, tip-over on uneven surface |

| Transport duct | Strain from lifting, struck by falling material |

| Install hangers | Overhead work strain, dropped tools |

| Lift duct | Crush injury, pinch points, strain |

| Connect sections | Sharp edges, awkward positions |

Step 4: Determine Controls

Apply the hierarchy of controls:

1. Elimination: Remove the hazard entirely

- Prefabricate at ground level instead of overhead

2. Substitution: Replace with something less hazardous

- Use lighter materials when possible

- Substitute mechanical lifting for manual

3. Engineering: Physical changes to the environment

- Guardrails on platforms

- Tool tethers for overhead work

- Proper lifting equipment

4. Administrative: Procedures and training

- Lift plans for heavy items

- Spotters for blind lifts

- Training on proper techniques

5. PPE: Personal protective equipment

- Hard hats

- Safety glasses

- Cut-resistant gloves

Always try to control hazards higher in the hierarchy first. PPE is the last resort.

The JHA Document

Template Structure

A practical JHA includes:

Header information:

- Task description

- Location

- Date

- Prepared by

- Reviewed by

Analysis table:

| Step | Hazards | Controls | Responsible |

|---|---|---|---|

| 1. Set up lift | Fall from platform | Inspect lift, use harness above 6' | Crew lead |

| Tip-over | Check surface level, deploy outriggers | Crew lead | |

| 2. Transport duct | Strain injury | Use mechanical aids for >50 lbs | All crew |

| Struck by | Clear path, team lift for long pieces | All crew |

Sign-off section:

- Crew acknowledgment signatures

- Date of review

- Supervisor verification

What Makes a Good JHA

Specific hazards: "Fall from height" not just "safety concern"

Actionable controls: "Install guardrails" not "be careful"

Clear responsibility: Who ensures each control is in place

Realistic steps: Matches how work is actually performed

Conducting JHA Reviews

Before Work Begins

The JHA isn't complete until the crew reviews it:

Pre-task briefing:

- Gather crew at work location

- Walk through each step

- Discuss each hazard and control

- Ask for additional hazards crew has identified

- Confirm everyone understands their role

- Document participation

When Conditions Change

Review again if:

- Work location changes

- Weather conditions change

- Crew composition changes

- New hazards are identified

- Scope of work changes

After Incidents or Near Misses

Every incident or near miss should trigger:

- JHA review

- Identification of what was missed

- Update to controls

- Re-briefing of crew

Common JHA Mistakes

Mistake 1: Generic JHAs

Wrong: Using the same JHA for every task Right: Tailoring JHAs to specific conditions

A JHA for pulling wire in a finished office is different from pulling wire in an active construction zone.

Mistake 2: Paperwork Exercise

Wrong: Filling out forms without crew discussion Right: Using the JHA as a planning and communication tool

The value is in the thinking and discussion, not the document.

Mistake 3: Ignoring Crew Input

Wrong: Supervisor creates JHA alone Right: Involving workers who do the task

Workers know the hazards. They've experienced near misses. Their input makes JHAs realistic.

Mistake 4: Set and Forget

Wrong: Creating JHA once and never updating Right: Living documents that evolve with the work

Conditions change. New hazards emerge. JHAs must keep pace.

Mistake 5: All PPE Solutions

Wrong: "Wear safety glasses" as the only control Right: Using the full hierarchy of controls

PPE should be supplementary, not primary.

Trade-Specific Hazards

Electrical

| Task | Key Hazards | Critical Controls |

|---|---|---|

| Panel work | Arc flash, shock | LOTO, arc-rated PPE, voltage verification |

| Wire pulling | Strain, electrical contact | Mechanical aids, circuit verification |

| Testing | Shock, burns | Proper test equipment, qualified personnel |

Mechanical

| Task | Key Hazards | Critical Controls |

|---|---|---|

| Equipment rigging | Crush, fall | Lift plan, certified rigging |

| Overhead work | Falls, dropped objects | Fall protection, tool tethers |

| Brazing/welding | Burns, fire, fumes | Hot work permit, fire watch, ventilation |

Plumbing

| Task | Key Hazards | Critical Controls |

|---|---|---|

| Excavation work | Cave-in, utilities | Competent person, locate tickets |

| Pressure testing | Rupture, projectiles | Pressure limits, clear zone |

| Sanitary connections | Biological hazards | PPE, hygiene protocols |

Using AI for JHA Development

Identifying Hazards

I'm creating a JHA for installing VRF condensing units on a rooftop.

List potential hazards for each of these steps:

1. Rigging equipment to roof

2. Positioning units

3. Making refrigerant connections

4. Making electrical connections

5. Startup and testing

Consider: fall hazards, rigging hazards, electrical hazards,

refrigerant hazards, and environmental factors.

Suggesting Controls

For this hazard, suggest controls using the hierarchy:

Hazard: Installing overhead pipe supports requires working

from a ladder with hands occupied.

Provide at least one option for:

- Elimination

- Substitution

- Engineering

- Administrative

- PPE

Reviewing Completeness

Review this JHA for completeness:

[Paste your JHA]

Check for:

- Missing steps

- Unaddressed hazards

- Insufficient controls

- Controls that are only PPE

- Unclear responsibilities

Building a JHA Library

Organizing by Task Type

Create categories:

- Electrical tasks: Panel installation, wire pulling, terminations

- Mechanical tasks: Equipment setting, ductwork, piping

- Plumbing tasks: Underground, overhead, testing

- General tasks: Material handling, housekeeping, ladder use

Template JHAs

Develop templates for routine work:

- Start with complete hazard identification

- Include standard controls

- Leave space for site-specific additions

- Require review and customization before use

Templates save time while ensuring thorough coverage.

Continuous Improvement

Track JHA effectiveness:

- Which JHAs are used most often?

- Which tasks have incidents despite JHAs?

- What hazards are being missed?

- What controls aren't being followed?

Use this data to improve your JHA library.

What's Next

JHAs address task-specific hazards. The next level is connecting these to your overall safety program—toolbox talks, training, and incident investigation—so safety becomes part of how your crews think about every task.

TL;DR

- JHAs identify hazards and controls before work begins—not paperwork, a thinking process

- Break tasks into steps, identify what could go wrong, apply controls from the hierarchy

- Elimination and engineering controls are more effective than PPE alone

- Review JHAs with crews before work and when conditions change

- Use templates for efficiency but customize for specific conditions

- Track incidents and near misses to continuously improve your JHAs