The OSHA inspector arrives on your jobsite. Your crew is working overhead without fall protection. Another is in an electrical room with the door propped open and no arc flash PPE.

Within an hour, you're facing citations that could cost tens of thousands of dollars—and worse, put your EMR and bidding ability at risk.

Understanding OSHA compliance isn't optional for MEP subcontractors.

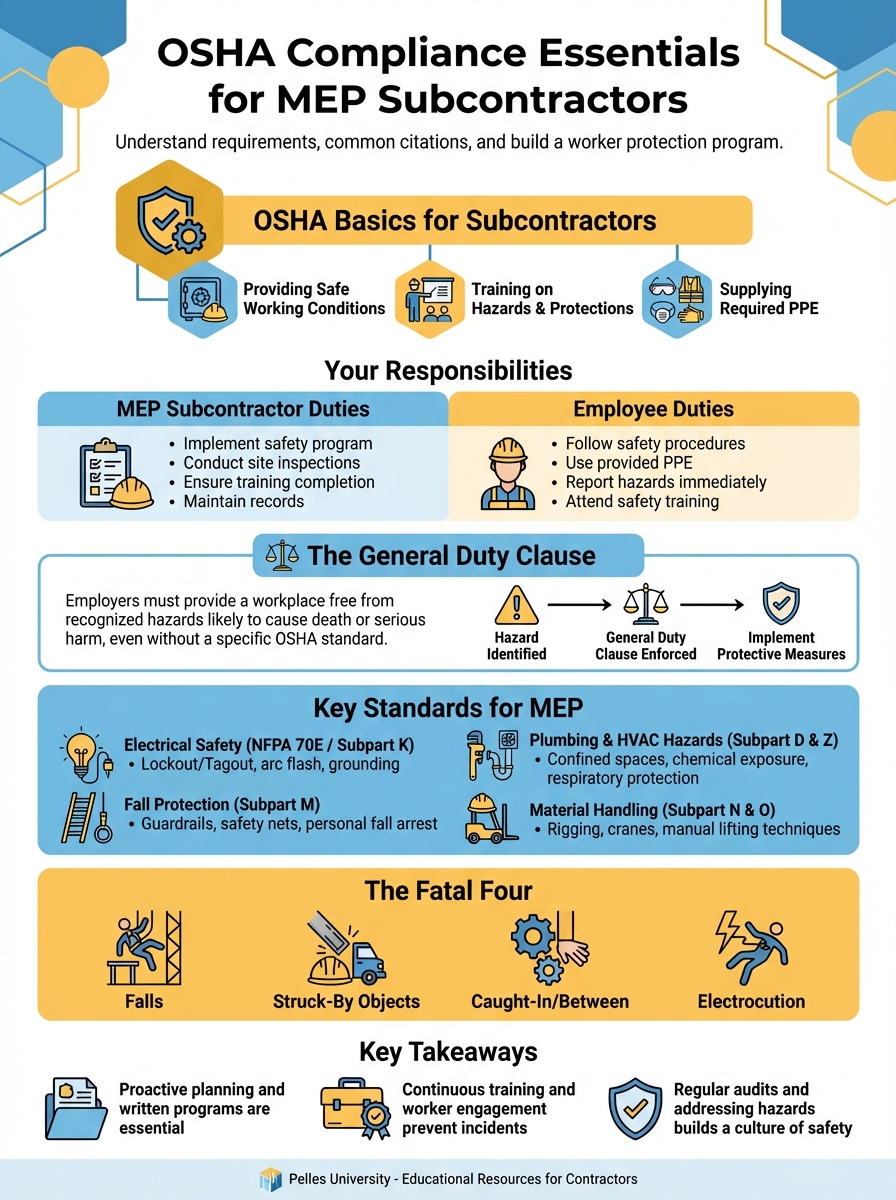

OSHA Basics for Subcontractors

Your Responsibilities

As an employer on a construction site, you're responsible for:

Your employees:

- Providing safe working conditions

- Training on hazards and protections

- Supplying required PPE

- Maintaining safety records

Multi-employer site:

- Controlling hazards you create

- Not exposing your workers to others' hazards

- Correcting hazards within your control

- Warning of hazards you can't correct

Being a subcontractor doesn't reduce your obligations.

The General Duty Clause

Even where no specific standard exists:

"Each employer shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm." — Section 5(a)(1), OSH Act

If you know a hazard exists and don't address it, you can be cited even without a specific regulation.

Key Standards for MEP

29 CFR 1926 (Construction):

- Subpart C: General Safety and Health

- Subpart E: Personal Protective Equipment

- Subpart K: Electrical

- Subpart L: Scaffolding

- Subpart M: Fall Protection

- Subpart X: Stairways and Ladders

29 CFR 1910 (General Industry):

- 1910.147: Lockout/Tagout

- 1910.1200: Hazard Communication

- 1910.134: Respiratory Protection

- 1910.146: Permit-Required Confined Spaces

Some general industry standards apply to construction work.

The Fatal Four

Four hazards cause most construction fatalities:

1. Falls (38.7%)

Requirements:

- Fall protection at 6 feet or above

- Guardrails, safety nets, or personal fall arrest

- Controlled access zones and safety monitoring (limited use)

- Training before exposure to fall hazards

MEP-specific concerns:

- Ladder work transitions to unprotected areas

- Work near floor openings and shafts

- Roof access for equipment installation

- Elevated platforms and lifts

2. Struck-By (9.4%)

Requirements:

- Falling object protection

- Vehicle and equipment safety

- Proper material storage and securing

- Warning systems for overhead work

MEP-specific concerns:

- Tools and materials dropped from height

- Pipe and conduit stored unsecured

- Material handling in congested areas

- Coordination with other trades' activities

3. Electrocution (8.3%)

Requirements:

- Lockout/tagout for energy isolation

- Qualified workers for electrical tasks

- Proper clearances from energized parts

- GFCI protection for tools and equipment

MEP-specific concerns:

- Working on or near energized equipment

- Temporary power connections

- Underground and overhead utilities

- Testing and energizing new systems

4. Caught-In/Between (7.3%)

Requirements:

- Machine guarding

- Trench and excavation protection

- Lockout of mechanical energy

- Safe entry to confined spaces

MEP-specific concerns:

- Mechanical equipment with moving parts

- Excavation for underground utilities

- Work in mechanical rooms

- Material handling equipment

Common MEP Citations

Electrical (Subpart K)

Frequent violations:

| Citation Area | Standard | Common Issue |

|---|---|---|

| GFCI protection | 1926.404(b)(1) | No GFCI on temporary power |

| Flexible cords | 1926.405(a)(2) | Damaged cords, improper use |

| Clearances | 1926.405(b)(1) | Working too close to energized parts |

| Guarding | 1926.405(b)(1) | Open cabinets, exposed terminals |

Lockout/Tagout (1910.147):

| Element | Requirement |

|---|---|

| Written program | Documented procedures for equipment |

| Training | All affected and authorized employees |

| Devices | Locks that can't be removed without key |

| Verification | Test after isolation to confirm zero energy |

Fall Protection (Subpart M)

Frequent violations:

| Citation Area | Standard | Common Issue |

|---|---|---|

| Unprotected edges | 1926.501(b)(1) | Work near openings without protection |

| Ladder use | 1926.1053 | Wrong type, damaged, improper setup |

| Scaffolding | 1926.451 | Incomplete platforms, no guardrails |

| Training | 1926.503 | No documented fall protection training |

Hazard Communication

Frequent violations:

| Citation Area | Standard | Common Issue |

|---|---|---|

| Written program | 1910.1200(e) | No site-specific HazCom program |

| SDS access | 1910.1200(g) | Workers can't access Safety Data Sheets |

| Container labels | 1910.1200(f) | Secondary containers unlabeled |

| Training | 1910.1200(h) | No documented chemical training |

Building a Compliance Program

Element 1: Written Programs

Required written programs for most MEP contractors:

Essential programs:

- Hazard Communication Program

- Fall Protection Plan (site-specific)

- Lockout/Tagout Procedures

- Electrical Safety Program

- Respiratory Protection (if respirators used)

- Confined Space Entry (if applicable)

Program components:

- Purpose and scope

- Responsibilities

- Procedures

- Training requirements

- Documentation

Element 2: Training

Required training topics:

| Topic | Who | When |

|---|---|---|

| Hazard Communication | All employees | Hire + new hazards |

| Fall Protection | Exposed workers | Before exposure |

| Electrical Safety | Electrical workers | Before work |

| LOTO | Authorized/affected | Before work + annually |

| PPE | All employees | Before use |

| Tool Safety | All employees | Before use |

Documentation:

- Training records with dates

- Topics covered

- Trainer qualification

- Employee signatures

Element 3: Competent Persons

OSHA requires "competent persons" for many activities:

Definition:

One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

Required for:

- Fall protection

- Scaffolding

- Excavations

- Cranes and rigging

- Electrical work (qualified person)

Documentation:

- Formal designation in writing

- Training records supporting competence

- Authority documented

Element 4: Inspections

Daily inspections:

- Work areas before work begins

- Equipment before each use

- PPE before each use

Periodic inspections:

- Scaffolds: Before each shift and after any event

- Ladders: Before each use

- Electrical equipment: Regular intervals

Documentation:

- Checklists with dates

- Corrective actions noted

- Inspector identified

Element 5: Recordkeeping

OSHA 300 Log:

- Required for employers with 11+ employees

- Record injuries/illnesses within 7 days

- Post annual summary February 1 - April 30

- Retain records for 5 years

What to record:

- Fatalities

- Injuries with days away from work

- Injuries with restricted work

- Medical treatment beyond first aid

- Loss of consciousness

- Significant diagnoses

Element 6: Incident Investigation

Investigate:

- All injuries requiring medical treatment

- All near misses with serious potential

- All property damage incidents

Documentation:

- Date, time, location

- People involved

- Description of incident

- Root cause analysis

- Corrective actions

- Follow-up verification

The OSHA Inspection Process

When OSHA Arrives

Your rights:

- Request to see credentials

- Request warrant (usually delays, not prevents)

- Accompany inspector during walkaround

- Take notes and photos

Best practices:

- Assign a management representative immediately

- Be cooperative but don't volunteer information

- Answer questions truthfully but briefly

- Document everything the inspector sees

During the Inspection

Opening conference:

- Inspector explains reason for visit

- You explain your operations

- Determine scope of inspection

Walkaround:

- Inspector observes conditions

- Interviews employees

- Takes photos and measurements

- Reviews documents

Closing conference:

- Inspector discusses findings

- You can provide additional information

- Timeline for citations discussed

After Receiving Citations

Options:

- Pay penalties and correct

- Request informal conference

- Contest citations formally

Timelines:

- 15 working days to contest

- Abatement dates specified

- Penalties due upon final order

Working with GCs on Safety

Site-Specific Requirements

GCs often have requirements beyond OSHA:

Common additions:

- 100% tie-off above 6 feet (vs. OSHA's fall protection options)

- Pre-task planning for all activities

- Specific PPE requirements

- Drug testing programs

- Safety orientation

Review GC requirements—they're usually contractual obligations.

Multi-Employer Liability

OSHA can cite multiple employers for the same hazard:

Creating employer: Created the hazard Exposing employer: Employees exposed Controlling employer: General control of site Correcting employer: Responsibility to correct

As a sub, you can be cited even for hazards you didn't create if your workers are exposed.

Reporting and Communication

Report immediately:

- All injuries to your workers

- Hazards that could affect others

- Near misses with serious potential

Document:

- Safety concerns you raise

- GC responses and timelines

- Your corrective actions

Using AI for Compliance

Interpreting Standards

Explain the requirements of 29 CFR 1926.502(d) for personal fall

arrest systems in plain language.

Include:

- Who does it apply to?

- What are the key requirements?

- What are common compliance mistakes?

Developing Programs

Help me create an outline for an Electrical Safety Program that

meets OSHA requirements for an MEP subcontractor.

Include:

- Required elements

- Training topics

- Documentation requirements

- Inspection procedures

Preparing for Inspections

I need to prepare for a potential OSHA inspection. Create a

self-inspection checklist for electrical work areas covering:

- General electrical safety

- Lockout/tagout compliance

- GFCI protection

- Cord and plug equipment

- Training documentation

Format as a checklist I can use weekly.

What's Next

Understanding OSHA requirements is foundational. The next step is building systems that make compliance automatic—safety documentation, toolbox talks, and crew engagement that embeds safety into daily operations.

TL;DR

- Know your Fatal Four: falls, struck-by, electrocution, caught-in/between

- Fall protection required at 6 feet in construction, GFCI for all tools

- Competent persons required for scaffolds, fall protection, excavations

- Written programs needed for HazCom, fall protection, LOTO, electrical

- Document training, inspections, and incidents—if it's not written, it didn't happen

- Multi-employer sites mean you can be cited for hazards you didn't create