Substantial completion is declared. The building opens. Everyone celebrates.

Six months later, you still don't have your final payment. The GC says your closeout package is incomplete. You can't find the warranty certificates. The as-builts weren't finished. The O&M manual is missing sections.

Now you're chasing paperwork instead of collecting money.

Good closeout starts long before the project ends.

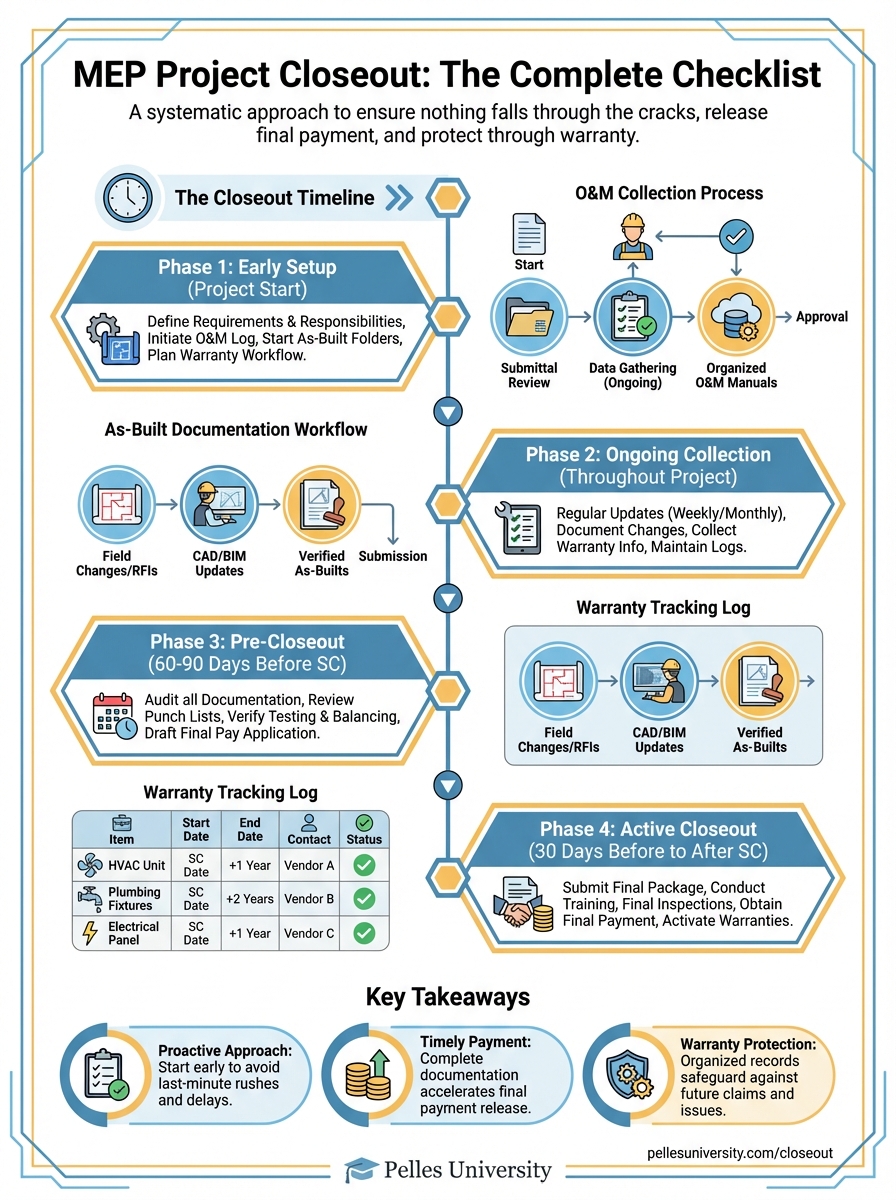

The Closeout Timeline

Phase 1: Early Setup (Project Start)

Establish systems:

- O&M collection process

- As-built documentation workflow

- Warranty tracking log

- Closeout checklist customized to contract

Understand requirements:

- Read Division 01 closeout specifications

- Review contract closeout provisions

- Note owner-specific requirements

- Identify unusual deliverables

Phase 2: Ongoing Collection (Throughout Project)

Progressive closeout:

- Collect O&M content as submittals are approved

- Mark as-builts as changes occur

- Track warranties from equipment deliveries

- Document testing and startup

Monthly review:

- Is O&M tracking current?

- Are as-builts being maintained?

- Are warranties being collected?

- Any gaps to address?

Phase 3: Pre-Closeout (60-90 Days Before SC)

Intensive preparation:

- Compile draft O&M for review

- Complete as-built markups

- Assemble warranty certificates

- Schedule training sessions

- Identify punch list items yourself

Coordination:

- Confirm GC closeout schedule

- Review owner training requirements

- Verify inspection schedules

- Confirm final testing dates

Phase 4: Active Closeout (30 Days Before to After SC)

Final deliverables:

- Submit final O&M manuals

- Submit record drawings

- Deliver warranty documentation

- Conduct owner training

- Complete punch list

- Final cleaning

Financial closeout:

- Prepare final invoice

- Document retainage due

- Provide lien releases

- Resolve any backcharges

The Master Closeout Checklist

Documentation Deliverables

O&M Manuals:

- All specification sections covered

- Equipment-specific data included

- Maintenance schedules compiled

- Warranty summary created

- Contact information current

- Format per specification

- Required copies produced

- Draft reviewed and accepted

- Final submitted

As-Built/Record Drawings:

- All field changes marked

- Hidden work documented

- Dimensions included

- CAD incorporation complete

- Format per specification

- Review against field conditions

- Final submitted

Warranty Documentation:

- All equipment warranties collected

- Warranty periods documented

- Start dates established

- Contact information compiled

- Certificates organized

- Summary sheet created

Test and Balance Reports:

- Air balance complete

- Water balance complete

- Reports formatted per spec

- Engineer review if required

- Final reports submitted

Commissioning Documentation:

- Functional performance tests complete

- Issues documented and resolved

- Final commissioning reports

- Trend data as required

Physical Completion

Punch List:

- Self-inspection completed

- Identified items corrected

- Formal punch walk attended

- All items addressed

- Verification walk completed

- Written acceptance received

Final Inspections:

- Code inspections passed

- Fire marshal approval

- AHJ sign-offs obtained

- Certificates of occupancy supported

Final Cleaning:

- Equipment cleaned

- Labels installed

- Covers and access doors in place

- Debris removed

- Work areas cleaned

Owner Training:

- Training scheduled

- Training materials prepared

- Training conducted

- Attendance documented

- Follow-up questions addressed

Financial Closeout

Final Invoice:

- All work invoiced

- Change orders included

- Retainage clearly identified

- Accurate totals

- Supporting documentation

Lien Releases:

- Progress lien releases current

- Final conditional release prepared

- Unconditional release after payment

Retainage:

- Retainage amount confirmed

- Release requirements understood

- Release request submitted

- Payment received

Backcharges:

- All backcharges reviewed

- Disputed items documented

- Resolutions reached

- Final accounting agreed

Administrative Closure

Contract Closeout:

- All change orders finalized

- Pending claims resolved

- Final contract value agreed

- Certificate of completion received

Internal Closeout:

- Project files organized

- Lessons learned documented

- Cost data captured

- Performance metrics recorded

Punch List Management

The Self-Punch Walk

Before the official punch walk, inspect your own work:

Walk with critical eyes:

- What would an owner notice?

- What would a GC call out?

- What doesn't meet spec?

- What's incomplete?

Document everything:

- Use the same format as formal punch

- Photo each item

- Assign to crews immediately

- Track to completion

Finding your issues first shows professionalism and reduces the formal punch list.

During Formal Punch

Be prepared:

- Know your scope boundaries

- Have contract documents for reference

- Bring camera/phone for documentation

- Have someone to take notes

During the walk:

- Document every item clearly

- Note location specifically

- Take photos

- Ask clarifying questions

- Identify disputes immediately

Immediately after:

- Review all items

- Flag scope disputes

- Categorize by urgency

- Assign to crews

Resolving Punch Items

Priority order:

- Life safety items

- Functional items

- Cosmetic items

- Disputed items (parallel track)

Track progress:

- Daily status updates

- Photo documentation of corrections

- Request re-inspection promptly

- Document acceptance

Handling Disputes

Not your scope:

- Document in writing

- Cite contract or drawings

- Request reassignment

- Don't do work pending resolution

Design issue, not installation:

- Document compliance with drawings

- Request direction via RFI

- Don't modify without approval

Owner Training

Understanding Requirements

Specification requirements:

- Who must be trained?

- What systems are covered?

- What duration is required?

- What documentation is needed?

Typical training scope:

- System overview

- Normal operation

- Maintenance procedures

- Troubleshooting basics

- Safety considerations

Conducting Training

Preparation:

- O&M manuals available

- Equipment accessible

- Operators present

- Training outline prepared

Documentation:

- Sign-in sheet with names/titles

- Topics covered checklist

- Duration of training

- Trainer identification

- Follow-up contact information

Delivery tips:

- Start with overview before details

- Demonstrate don't just explain

- Allow hands-on practice

- Encourage questions

- Provide O&M reference

Video Documentation

Some owners request video training:

- Record training sessions

- Create equipment-specific videos

- Provide digital copies

- Link to O&M documentation

Video extends training value beyond the session.

Warranty Management

Collecting Warranties

At equipment delivery:

- Request warranty certificate

- Note serial numbers

- Confirm warranty terms

- File for closeout

Registration requirements:

- Some warranties require registration

- Do this promptly—there may be deadlines

- Document registration confirmation

Warranty Summary

Create a master warranty summary:

| Equipment | Warranty | Start | End | Contact |

|---|---|---|---|---|

| AHU-1 | 1 yr parts/labor | 3/15/25 | 3/15/26 | (800) 555-1234 |

| Compressors | 5 yr compressor | 3/15/25 | 3/15/30 | (800) 555-1234 |

| Controls | 2 yr parts | 3/15/25 | 3/15/27 | (800) 555-5678 |

This summary becomes invaluable during warranty period.

Your Warranty Obligations

Understand your exposure:

- What's warranted in your contract?

- How long is your warranty?

- What's excluded?

- What voids the warranty?

Document starting conditions:

- Equipment installed properly

- Startup performed correctly

- Owner trained

- O&M provided

This protects you from warranty claims caused by owner error.

Financial Closeout

The Final Invoice

Include:

- Original contract amount

- All approved change orders

- Total contract value

- Amounts previously billed

- Retainage withheld

- Amount due

Attach:

- Detailed breakdown if required

- Signed change orders

- Lien releases

- Any required certifications

Retainage Release

Typical process:

- Substantial completion certified

- Closeout documentation accepted

- Punch list complete and verified

- Final invoice submitted

- Lien releases provided

- Retainage released

Accelerating release:

- Submit closeout documentation early

- Complete punch promptly

- Provide lien releases quickly

- Follow up consistently

Lien Releases

Types:

- Conditional: Releases rights contingent on payment

- Unconditional: Releases rights regardless of payment

Best practice:

- Provide conditional with final invoice

- Provide unconditional only after payment clears

- Never provide unconditional before receiving funds

Know your state's rules: Lien release requirements vary by state.

Common Closeout Failures

Failure: Documentation Gaps

Symptom: O&M missing sections, as-builts incomplete Impact: Final payment held, closeout delayed Prevention: Monthly documentation reviews throughout project

Failure: Lost Warranties

Symptom: Can't find warranty certificates at closeout Impact: Scrambling to get replacements, delays Prevention: Collect and file at equipment delivery

Failure: Training Not Scheduled

Symptom: Owner not available when you're ready Impact: Project holds waiting for training Prevention: Schedule training 60+ days in advance

Failure: Punch Disputes

Symptom: Items disputed at closeout, no resolution Impact: Closeout stalled on disputes Prevention: Address scope questions during construction

Failure: Financial Issues

Symptom: Backcharges appear at closeout, amounts disputed Impact: Final payment reduced, conflict Prevention: Address backcharges when issued, not at closeout

Using AI for Closeout

Creating Checklists

Create a closeout checklist for an MEP subcontractor on a

commercial office building project.

Include:

- Documentation deliverables

- Physical completion items

- Training requirements

- Financial closeout tasks

Format as a checklist with categories and checkboxes.

Drafting Training Outlines

Create an owner training outline for a variable refrigerant

flow (VRF) system installation covering:

- System overview

- Normal operation

- Maintenance requirements

- Troubleshooting basics

- Emergency procedures

Target duration: 2 hours

Audience: Facility maintenance staff

Responding to Closeout Issues

Help me draft a professional response to this GC closeout

rejection. They claim:

"O&M manual incomplete - missing wiring diagrams for VAV boxes"

Our position: Wiring diagrams were included in the controls

contractor's O&M section as specified. We provided product

data for VAV boxes which is our scope.

Write a response that's professional but firm.

The 90-Day Closeout Push

Days 90-60: Documentation Focus

- Complete O&M assembly

- Finish as-built markups

- Compile warranties

- Submit drafts for review

- Address review comments

Days 60-30: Physical Focus

- Self-punch walk

- Correct identified items

- Schedule training

- Coordinate inspections

- Final testing

Days 30-0: Closeout Sprint

- Formal punch walk

- Punch completion

- Deliver final documentation

- Conduct training

- Financial closeout

After SC: Follow-Through

- Retainage collection

- Warranty period begins

- Respond to any issues

- Document lessons learned

What's Next

Successful closeout gets your final payment and positions you well for warranty period. Your documentation becomes reference material for warranty support, and your professional closeout process builds reputation for future work.

TL;DR

- Start closeout preparation at project kickoff, not at the end

- Use a master checklist customized to your contract requirements

- Self-perform punch walks before official walks to reduce items

- Collect O&M content, as-builts, and warranties throughout construction

- Schedule owner training 60+ days in advance

- Provide conditional lien releases with final invoice, unconditional only after payment