The GC hands you a 47-item punch list. Twelve of them aren't yours. Eight are duplicates from last week. Three are already fixed. Two are design issues, not installation problems.

Welcome to punch list chaos.

Here's how to build a punch list workflow that actually works.

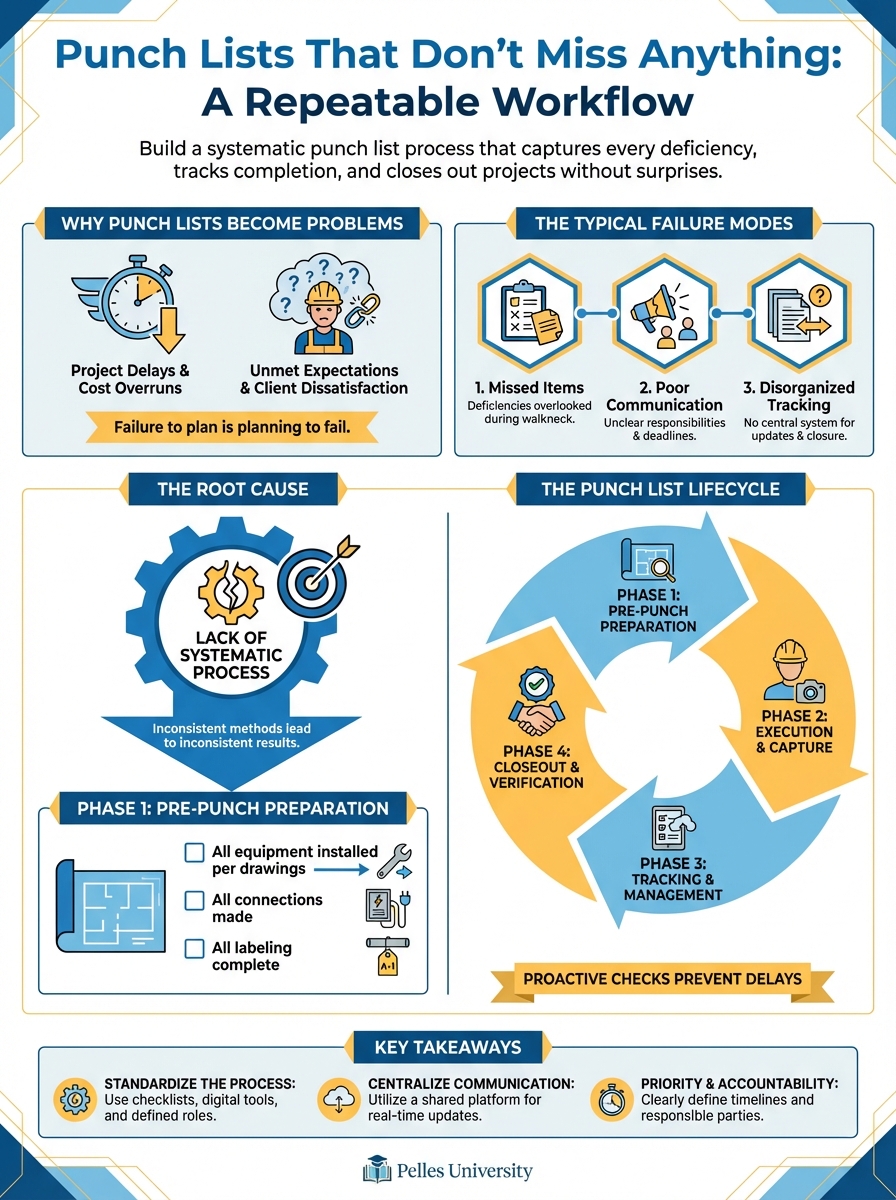

Why Punch Lists Become Problems

The Typical Failure Modes

Discovery chaos: Items appear randomly, documented inconsistently, scattered across emails and verbal reports.

Ownership confusion: "Is this ours or theirs?" becomes a daily debate.

Tracking gaps: Items get fixed but not recorded. Same items reappear.

Closeout drag: Last 5% of work takes 25% of the project timeline.

The Root Cause

Punch lists fail when they're reactive instead of systematic. A good process starts before the first deficiency is found.

The Punch List Lifecycle

Phase 1: Pre-Punch Preparation

Before formal punch, conduct your own walkthrough:

Self-inspection checklist:

- All equipment installed per drawings

- All connections made

- All labeling complete

- All access panels in place

- All testing complete

- All cosmetic issues addressed

Find your own problems before the GC finds them.

Phase 2: Formal Punch Walk

When the GC or owner conducts punch:

During the walk:

- Document every item with photo

- Note exact location

- Capture description as stated

- Ask clarifying questions immediately

- Note any disagreements on the spot

Immediately after:

- Review all items for accuracy

- Flag ownership disputes

- Identify duplicates

- Categorize by urgency

Phase 3: Execution

Prioritize items:

- Life safety first

- Functional issues second

- Cosmetic issues third

- Disputed items (parallel track)

Assign crews:

- Match skills to items

- Group by location

- Provide complete information

Track progress:

- Daily status updates

- Photo documentation of corrections

- Signature on completion

Phase 4: Verification

Your verification:

- Walk completed items

- Confirm correction meets standard

- Document with photos

GC/owner verification:

- Request formal sign-off

- Document accepted items

- Track remaining items

Phase 5: Closeout

Final documentation:

- All items closed or in dispute

- All photos filed

- All signatures obtained

- Written acceptance from GC

Building Your Punch List System

The Master Punch Log

Create one central log per project:

| # | Date | Location | Description | Photo | Owner | Status | Completed | Verified |

|---|---|---|---|---|---|---|---|---|

| 1 | 3/15 | Rm 203 | Diffuser scratched | Y | Ours | Open | - | - |

| 2 | 3/15 | Mech Rm | Panel label missing | Y | Ours | Complete | 3/16 | - |

| 3 | 3/15 | Rm 105 | Wrong paint color | Y | Not ours | Dispute | - | - |

Essential columns:

- Sequential number (never reuse)

- Date identified

- Specific location

- Clear description

- Photo reference

- Ownership determination

- Current status

- Completion date

- Verification date

Status Definitions

Use consistent status terminology:

Open: Item identified, not yet addressed In Progress: Crew assigned, work underway Complete: Work done, awaiting verification Verified: GC/owner confirmed correction Closed: Fully accepted and signed off Dispute: Ownership or validity contested Deferred: Agreed to address post-substantial completion

Location Standards

Use consistent location identifiers:

By room: "Room 203" By grid: "Grid D-5" By system: "AHU-3 serving Floor 2" By component: "VAV-2-17"

Precise locations speed corrections.

Photo Standards

Every punch item needs a photo:

The photo should show:

- The specific deficiency

- Enough context to find the location

- Date/time stamp

Naming convention:

[Punch#]_[Location]_[Date].jpg

Example: 027_Rm203_031525.jpg

Self-Performing Pre-Punch

The 90% Complete Walk

When work is 90% complete, walk it yourself:

For each area:

- Check against drawings

- Check against spec requirements

- Check against your QC checklist

- Look with owner's eyes

Document what you find:

- Same format as formal punch

- Assign to your crews immediately

- Track to completion

Fixing your own findings is cheaper than responding to punch lists.

The Pre-Punch Meeting

Before formal punch walk:

Confirm:

- Is the area ready? (Other trades complete?)

- Is access clear?

- Is temporary protection removed?

- Are final inspections done?

Coordinate:

- Who's attending?

- What's the scope of this walk?

- How are items being documented?

- What's the turnaround expectation?

Set expectations before the walk.

Handling Punch Disputes

"This Isn't Ours"

When an item is assigned to you incorrectly:

Response process:

- Document your position in writing

- Cite specific evidence (drawing, spec, scope of work)

- Request reassignment

- Don't perform work pending resolution

Example response: "Punch item #34 (thermostat programming) is assigned to our trade. Per specification Section 23 09 00, Paragraph 3.2.1, thermostat programming is by the controls contractor. Please reassign. We are not authorized to modify controls settings."

"This Is a Design Issue"

When punch describes a design problem:

Response process:

- Document that installation matches documents

- Reference specific drawing/spec

- Request RFI or design clarification

- Do not modify without direction

Example response: "Punch item #41 notes diffuser noise in Room 212. Our installation matches Drawing M-301 and approved submittal. If the diffuser selection is causing noise concerns, please provide design direction via RFI for corrective action."

"This Was Already Fixed"

When duplicate items appear:

Response process:

- Reference the previous completion

- Provide photo evidence

- Request removal from list

Example response: "Punch item #52 duplicates punch item #18, which was completed on 3/10 and verified by your superintendent on 3/12. Please see attached photo documentation and remove from current list."

Tracking Efficiency

Metrics That Matter

Punch density: Items per area

- High density = quality problems

- Consistent areas = systemic issues

Resolution time: Days from identification to verification

- Target: 48-72 hours for simple items

- Track reasons for delays

Dispute rate: Percentage contested

- High rate = scope clarity issues

- Track resolution outcomes

Return rate: Items that come back

- High rate = incomplete corrections

- Track by crew for training opportunities

Weekly Punch Review

Every week during closeout:

Review:

- All new items logged

- All ownership disputes documented

- All completions recorded

- All verifications requested

- Any patterns to address

Prepare:

- Crew assignments for next week

- Materials needed for corrections

- Access coordination required

- Verification walks scheduled

Using AI for Punch List Management

Categorizing Items

Categorize these punch list items by trade and priority:

[Paste punch list]

Categories:

- Mechanical

- Electrical

- Plumbing

- Not our scope

- Design issue

Priority:

- High (life safety/functional)

- Medium (completion)

- Low (cosmetic)

Drafting Dispute Responses

Draft a professional response disputing this punch list item:

Item: [Description]

Assigned to: Our trade

Reason it's not ours: [Explanation]

Evidence: [Drawing/spec reference]

Keep it factual and professional.

Generating Pre-Punch Checklists

Generate a pre-punch walk checklist for:

Trade: [Your trade]

Area: [Location]

Spec sections: [Relevant sections]

Include items an owner would notice and items an inspector would check.

The Final Walk Mindset

When you do pre-punch, think like the owner:

Visual quality:

- Are finishes consistent?

- Are labels readable?

- Are grilles/covers straight?

- Is work clean and professional?

Functional quality:

- Does it operate correctly?

- Are controls responsive?

- Is access maintained?

- Are safety items visible?

Documentation quality:

- Are as-builts current?

- Is O&M complete?

- Are warranties ready?

- Is training scheduled?

Finding items before they find you is the professional approach.

What's Next

A systematic punch list workflow catches deficiencies. The next step is connecting this to your closeout documentation—so the final paperwork is ready when the last punch item is verified.

TL;DR

- Conduct self-inspection before formal punch—find your problems first

- Use a centralized log with consistent location and photo standards

- Define clear status stages: Open → In Progress → Complete → Verified → Closed

- Dispute incorrect assignments in writing with evidence

- Track metrics: punch density, resolution time, dispute rate, return rate