The inspector is coming Tuesday. Do you have a checklist, or are you walking the job hoping you don't miss anything?

Quality control shouldn't depend on memory. It should depend on a checklist built from the actual project requirements.

Here's how to generate trade-specific QA/QC checklists in minutes.

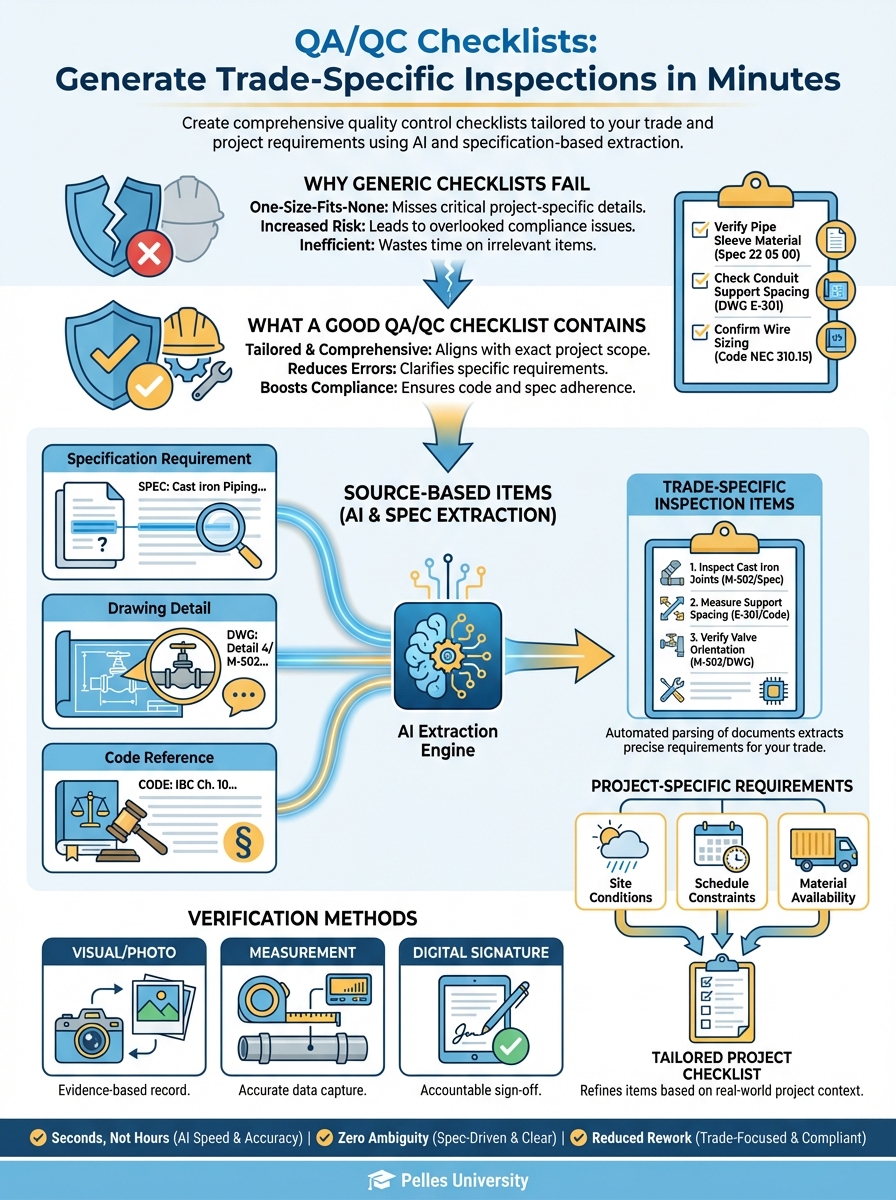

Why Generic Checklists Fail

Most companies use one of two approaches:

The generic checklist: Same form for every project. Doesn't match the actual specifications. Misses project-specific requirements.

The memory method: Walk the job with experienced eyes. Works until it doesn't. Can't be delegated.

Both approaches have the same problem: they're not connected to the actual contract documents.

What a Good QA/QC Checklist Contains

Source-Based Items

Every checklist item should trace back to a source:

- Specification requirement

- Drawing detail

- Code reference

- Manufacturer instruction

If you can't cite why you're checking something, why are you checking it?

Project-Specific Requirements

Generic "check for level" becomes:

- Level within 1/8" per 10' (per spec)

- Verify slope direction per drawing

- Confirm drain locations match layout

Specific items get specific results.

Verification Methods

Each item should specify how to verify:

- Visual inspection

- Measurement with tool

- Witness test

- Documentation review

Clear methods mean consistent results.

Building Checklists from Specifications

Step 1: Identify Applicable Sections

For each trade/system, identify relevant spec sections:

Ductwork Installation:

- 23 31 13 - Metal Ducts

- 23 07 13 - Duct Insulation

- 23 05 29 - Hangers and Supports

- 23 33 00 - Duct Accessories

Hydronic Piping:

- 23 21 13 - Hydronic Piping

- 23 07 19 - Piping Insulation

- 23 05 29 - Hangers and Supports

- 23 21 23 - Hydronic Pumps

Step 2: Extract Execution Requirements

Go to Part 3 of each section and extract:

- Installation requirements

- Tolerances

- Testing requirements

- Documentation requirements

Step 3: Extract Quality Requirements

Look for:

- "Quality assurance" in Part 1

- "Examination" at start of Part 3

- "Field quality control" in Part 3

- Referenced standards (SMACNA, etc.)

Step 4: Compile and Organize

Organize items by:

- Installation phase

- Location/area

- Priority (critical vs. standard)

Using AI to Generate Checklists

Speed up the process with AI extraction:

Generate a QA/QC checklist for HVAC ductwork installation based on these specifications:

[Paste relevant spec sections]

Include:

1. Pre-installation verification items

2. Installation inspection points

3. Testing requirements

4. Documentation requirements

For each item, cite the specification reference.

Format as a checklist I can print and use in the field.

Sample AI-Generated Checklist

DUCTWORK INSTALLATION QA/QC CHECKLIST

Pre-Installation:

- Shop drawings approved (23 31 13, 1.5.A)

- Duct material matches spec - galvanized steel per ASTM A653 (23 31 13, 2.1.A)

- Gauges match schedule (23 31 13, 2.1.D)

- Sealant/gaskets on site (23 31 13, 2.2)

Fabrication Verification:

- Rectangular joints per SMACNA Class A (23 31 13, 2.3.A)

- Round duct spiral seams continuous (23 31 13, 2.3.B)

- Fittings match SMACNA standards (23 31 13, 2.4)

Installation:

- Hangers per spec spacing: [X ft max] (23 05 29, 3.2.A)

- Hanger type matches spec (23 05 29, 2.1)

- Duct sealed per pressure class (23 31 13, 3.2.C)

- Access doors provided per schedule (23 33 00, 3.2)

- Fire dampers installed per drawing (23 33 46, 3.2)

Testing:

- Duct leakage test completed (23 31 13, 3.4.A)

- Test documentation submitted (23 31 13, 3.4.B)

- Leakage within [X] CFM per 100 SF (23 31 13, 3.4.C)

Trade-Specific Checklist Templates

Electrical Panel Installation

Pre-Installation:

- Panel submittal approved

- Location verified per drawing

- Wall/structure ready for mounting

- Clearances verified: [X" front], [X" sides]

Installation:

- Panel level within tolerance

- Properly secured to structure

- Grounding connected per spec

- Neutral-ground bond verified

- Knockouts not left open

Terminations:

- Wire sizing matches schedule

- Torque specifications met

- Labeling complete per code

- Directory installed and accurate

Testing:

- Megger test completed

- Ground fault circuits tested

- Arc fault circuits tested

- Documentation complete

Plumbing Rough-In

Pre-Installation:

- Drawing routing verified

- Penetration locations marked

- Sleeve sizes confirmed

- Fixture rough-in dimensions confirmed

Piping:

- Pipe material per spec

- Fittings per spec (no prohibited types)

- Slope verified: [X" per foot] drain

- Hangers per spec spacing

- Firestopping at penetrations

Testing:

- Pressure test setup ready

- Test pressure: [X PSI] for [X hours]

- Inspection scheduled

- Test documentation prepared

VAV Box Installation

Pre-Installation:

- Unit matches schedule

- Capacity verified

- Controller matches spec

- Access location confirmed

Mounting:

- Level and secure

- Clearance for access

- Duct connections proper

- Insulation continuous

Connections:

- Hot water piping connected (if applicable)

- Electrical power connected

- Controls wired per diagram

- Damper operation verified

Startup:

- Actuator calibrated

- Airflow measured

- Controls commissioned

- Documentation complete

Phased Checklists

Organize checklists by project phase:

Phase 1: Rough-In

- Routing and locations

- Hangers and supports

- Sleeves and penetrations

- Before cover-up items

Phase 2: Equipment Setting

- Equipment placement

- Connections

- Leveling and anchoring

- Access verification

Phase 3: Trim and Finish

- Fixtures and devices

- Labeling

- Final connections

- Appearance

Phase 4: Testing and Commissioning

- System tests

- Documentation

- Witness inspections

- Deficiency correction

Making Checklists Actually Work

Keep It Visible

Checklists in the office don't help the field. Make them:

- Printed and on clipboards

- Mobile-accessible

- Posted at work areas

Daily Use, Not Weekly

Checklists work when used daily:

- Pre-work check

- During work verification

- End-of-day confirmation

Waiting until inspection time defeats the purpose.

Document Results

Every checklist should capture:

- Date completed

- Who verified

- Pass/fail status

- Notes on deficiencies

This creates the quality record you need.

Address Failures Immediately

When items fail:

- Note the deficiency

- Assign correction

- Re-inspect after correction

- Document resolution

Punch list items should come from checklists, not surprises.

The Weekly QC Review

Build QA/QC into your weekly rhythm:

Monday: Review week's planned work, prepare relevant checklists

Daily: Use checklists during installation

Friday: Review completed checklists, note patterns, prepare for next week

Pattern Recognition

Track failures over time:

- What items fail repeatedly?

- Which crews have issues?

- What specs cause confusion?

Patterns indicate training needs or process problems.

AI-Generated vs. Template Checklists

When to Generate Fresh

- New project with unique specs

- Unfamiliar equipment

- Complex systems

- High-stakes inspections

When to Use Templates

- Standard installations

- Repeat project types

- Common equipment

- Routine inspections

The Hybrid Approach

Start with a template, then:

- Run AI extraction on project specs

- Compare to template

- Add project-specific items

- Remove non-applicable items

- Update spec references

Best of both worlds: proven structure plus project specificity.

What's Next

QA/QC checklists catch issues during installation. The next step is building punch list workflows—so the issues you do find get tracked and resolved systematically.

TL;DR

- Generic checklists miss project-specific requirements—build from actual specs

- Use AI to extract requirements from specification sections in minutes

- Organize by phase: rough-in, equipment, trim, commissioning

- Use checklists daily, not just before inspections

- Track failure patterns to identify training needs and process improvements