The foreman reads the same script about ladder safety for the third time this month. Half the crew is on their phones. The other half is staring at their boots.

Everyone signs the sheet. No one remembers anything.

This is what toolbox talks look like when they're treated as paperwork instead of communication.

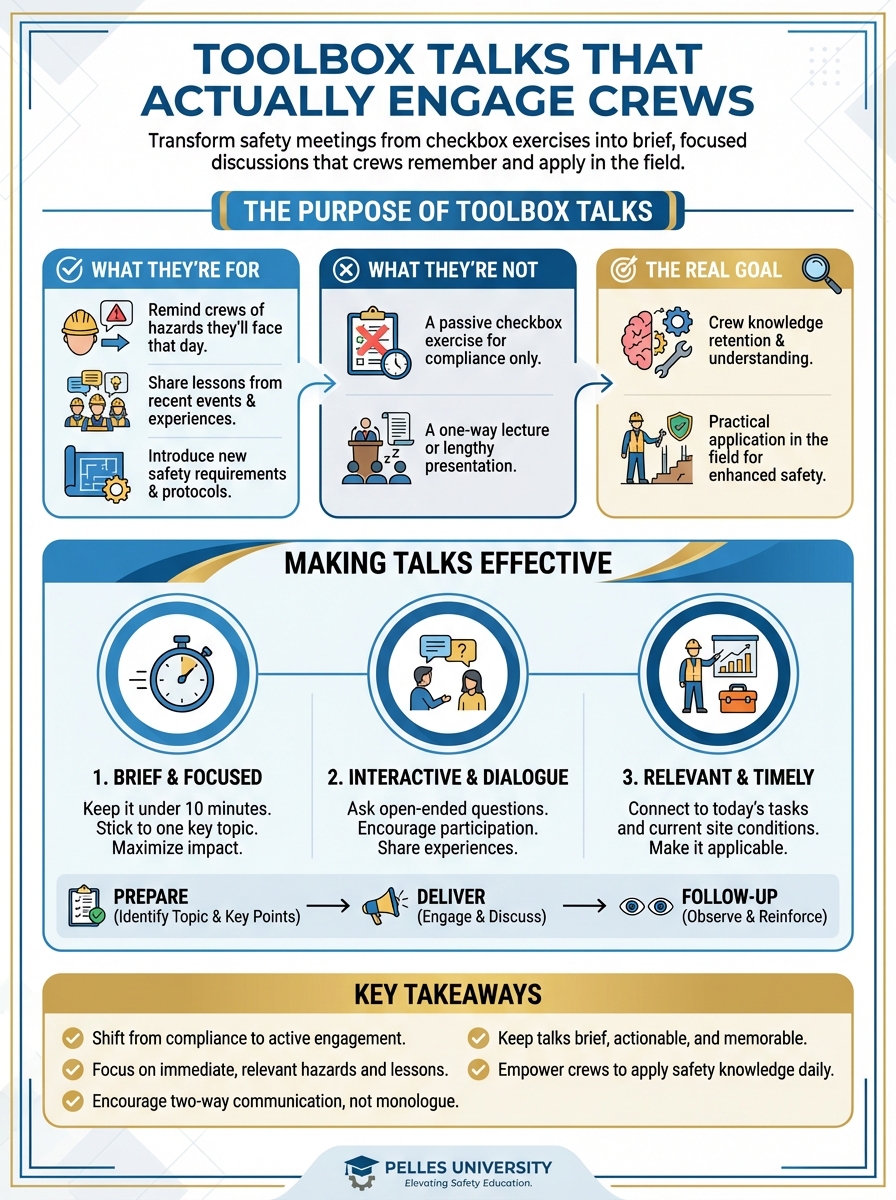

The Purpose of Toolbox Talks

What They're For

Toolbox talks are brief safety discussions that:

- Remind crews of hazards they'll face that day

- Share lessons from recent events

- Introduce new safety requirements

- Create space for crew questions and concerns

What They're Not

Toolbox talks are not:

- Comprehensive training (that's separate)

- Punishment for past incidents

- Reading aloud from OSHA regulations

- Checkbox exercises for documentation

The Real Goal

One key takeaway that crews remember and apply.

That's it. If your crew walks away with one thing they'll do differently, the talk succeeded.

Making Talks Effective

Keep Them Short

Target: 5-10 minutes

Attention drops sharply after 10 minutes. A focused 5-minute talk beats a meandering 30-minute meeting.

Structure:

- Hook (30 seconds): Why this matters today

- Core content (3-5 minutes): The key points

- Discussion (2-3 minutes): Questions and crew input

- Takeaway (30 seconds): The one thing to remember

Make Them Relevant

Wrong approach: Generic ladder safety on a day with no ladder work

Right approach: Ladder safety when crews are actually using ladders

Connect every topic to:

- Today's specific tasks

- This week's conditions

- Recent events on this project

- Hazards crews will actually face

Use Real Examples

Generic: "Falls are dangerous."

Specific: "Yesterday, I saw someone lean too far reaching for conduit. Here's what almost happened..."

Real stories from your jobsite, your company, or your experience stick better than statistics.

Involve the Crew

Don't: Lecture for 10 minutes Do: Ask questions and listen to answers

Good questions:

- "What's the most dangerous part of what we're doing today?"

- "Has anyone seen this go wrong before?"

- "What would you do if you saw someone doing this unsafely?"

Crews who talk are crews who think.

Timing and Frequency

Daily Talks

For high-hazard activities:

- Before starting work each day

- When new hazards are introduced

- After any safety incident

Topics tied to that day's work.

Weekly Talks

Minimum requirement for most sites:

- Rotating through key topics

- Addressing seasonal hazards

- Reviewing company safety focus areas

Plan topics ahead but adjust for current conditions.

Triggered Talks

Immediate response to:

- Near misses (within 24 hours)

- New equipment or tools

- Changed conditions

- Weather events

- Incidents on similar projects

Strike while the learning is fresh.

Topic Selection

Connect to Current Work

Example calendar:

| Week | Scheduled Work | Toolbox Topic |

|---|---|---|

| 1 | Underground rough-in | Trench safety, utility strikes |

| 2 | Overhead rough-in | Fall protection, ladder safety |

| 3 | Equipment setting | Rigging, pinch points |

| 4 | Testing systems | LOTO, pressure testing |

Match topics to exposure.

Seasonal Considerations

Summer:

- Heat illness prevention

- Sun exposure

- Hydration requirements

- Working in hot spaces

Winter:

- Cold stress

- Slips on ice

- Shortened daylight

- Space heater hazards

Spring/Fall:

- Weather changes

- Transitional PPE

- Allergies and outdoor work

Trade-Specific Topics

Electrical:

- Arc flash awareness

- LOTO procedures

- Testing equipment safety

- Working near energized parts

Mechanical:

- Rigging and lifting

- Overhead work hazards

- Hot work safety

- Confined space entry

Plumbing:

- Excavation safety

- Pressure testing

- Biological hazards

- Tool safety for cutting

Delivery Techniques

Location Matters

Good locations:

- At the work area itself

- Where you can point to actual hazards

- Where everyone can see and hear

Bad locations:

- Remote trailer far from work

- Noisy areas requiring shouting

- Areas with distractions

When possible, deliver talks at the work location.

Visual Aids

Effective visuals:

- Actual equipment being discussed

- Photos of correct vs. incorrect

- Damaged PPE examples

- Simple diagrams on a whiteboard

Ineffective visuals:

- Dense text-heavy slides

- Generic stock photos

- Complicated charts

Keep it simple and tangible.

Speaking Tips

Do:

- Make eye contact

- Use names

- Move around the group

- Ask questions

- Pause for responses

Don't:

- Read from a script word-for-word

- Talk to your clipboard

- Rush through to finish

- Dismiss questions

- Lecture or scold

You're leading a conversation, not giving a presentation.

Handling Discussions

Encouraging Participation

Start with easy questions:

- "Anyone used this equipment before?"

- "What's the weather supposed to be today?"

- "Who's worked in spaces like this before?"

Then move to safety questions:

- "What hazards should we watch for?"

- "What's our plan if something goes wrong?"

- "Any concerns about today's work?"

Dealing with Silence

If crews don't respond:

- Ask someone by name (respectfully)

- Share your own experience first

- Ask about past projects

- Give them a moment—silence is okay

Don't answer your own questions immediately.

Addressing Wrong Answers

When someone gives an unsafe answer:

Wrong: "No, that's completely wrong."

Right: "I can see how you'd think that. Here's what I've seen work better..."

Correct without embarrassing. You want people to speak up next time.

When Someone Raises a Concern

Take it seriously:

- Thank them for raising it

- Discuss how to address it

- Follow up visibly

- Report back at next talk

Ignored concerns = silent crews.

After Near Misses

The 24-Hour Talk

When something almost goes wrong:

Do immediately:

- Stop work if needed

- Gather facts while fresh

- Plan a talk for next morning

The talk structure:

- What happened (facts only)

- What could have happened

- Why it happened

- How we prevent it

- Questions and discussion

No Blame, Just Learning

Focus on systems, not individuals:

Wrong: "John almost fell because he was being careless."

Right: "We had a near miss at the roof edge. Let's talk about what contributed and how we prevent it."

Blame shuts down reporting. Learning keeps incidents visible.

Documenting Near Miss Talks

Record:

- Date and time

- Description of near miss

- Discussion points

- Corrective actions decided

- Attendees

This documentation shows your safety program is responsive.

Documentation

What to Record

For every toolbox talk:

- Date and time

- Location

- Topic covered

- Key points discussed

- Questions raised

- Attendee signatures

Why It Matters

Documentation proves:

- Training occurred

- Topics were covered

- Crews were informed

In an incident investigation or OSHA inspection, this matters.

Simple Format

TOOLBOX TALK RECORD

Date: ___________ Time: ___________

Project: ___________

Presented by: ___________

Topic: ___________

Key Points Discussed:

1. ___________

2. ___________

3. ___________

Questions/Concerns Raised: ___________

Attendees:

Name Signature

___________ ___________

___________ ___________

Keep it simple. Complex forms don't get completed.

Building a Talk Library

Organizing Topics

Create categories:

General safety:

- PPE usage

- Housekeeping

- Emergency procedures

- Hazard reporting

Task-specific:

- Ladder safety

- Scaffold safety

- Power tool safety

- Material handling

Trade-specific:

- Electrical safety

- LOTO procedures

- Hot work safety

- Pressure testing

Template Development

For each topic, prepare:

- Main talking points (3-5 bullet points)

- Discussion questions (2-3 questions)

- Common misconceptions to address

- Connection to current work (customize)

Templates save time while allowing customization.

Using AI for Toolbox Talks

Generating Topics

Create a 5-minute toolbox talk outline for MEP crews about

working in hot weather.

Include:

- Opening hook

- 3 key points

- 2 discussion questions

- One clear takeaway

Keep it conversational, not technical.

Customizing for Conditions

Adapt this ladder safety toolbox talk for crews working in

a finished hospital wing:

[Paste your standard talk]

Consider:

- Hospital-specific concerns

- Patient and staff traffic

- Floor surfaces

- Space constraints

Post-Incident Talks

Help me prepare a toolbox talk about a near miss:

What happened: Worker's ladder slipped while reaching for

conduit, caught themselves on nearby pipe.

Create a non-blaming talk that:

- Describes what happened

- Identifies contributing factors

- Discusses prevention

- Encourages reporting

What's Next

Effective toolbox talks build awareness. The next level is connecting this to your broader safety documentation system—incident tracking, training records, and compliance documentation that work together to protect crews and your company.

TL;DR

- Keep talks to 5-10 minutes with one clear takeaway

- Connect every topic to that day's actual work

- Use real examples and involve the crew in discussion

- Conduct talks at the work location when possible

- Discuss near misses within 24 hours without blame

- Document attendance, topics, and discussions for every talk